The outside of petrol tanker can be customized. The internal breathing valve is used to keep the internal and external pressure equilibrium. If the pressure inside the petrol tanker is too high, the breather valve will open. It plays vital role to release excess gas to avoid build-up of gas. Keeping the tank body safe is significant to avoid the risk of explosion.

1. Oil tank structure design

1. Material selection

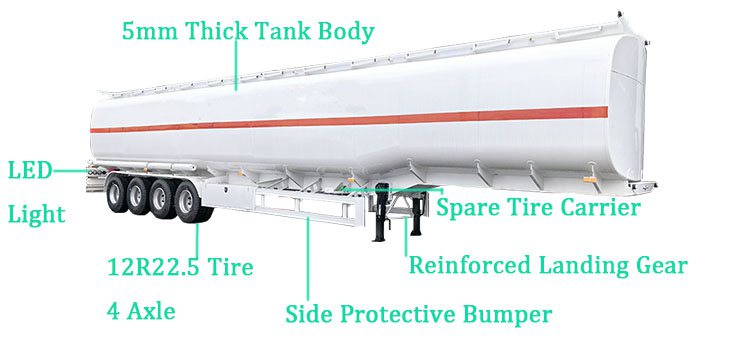

The choice of materials is vital in the structure design of the petrol tanker. The petrol tanker with high strength T700 owns good anti-corrosion performance. They are also very powerful. They are able to withstand all kinds of environmental factors effectively. The 5 mm thick tank body contributes to higher safety and durability for petrol tanker. Thus, the risk of leakage due to outside shock is decreased.

4 Axle 70000L Petrol Tanker Price in Mali

4 Axle 70000L Petrol Tanker Price in Mali

4 Axle 70000L Petrol Tanker Price in Mali

4 Axle 70000L Petrol Tanker Price in Mali

Model: 4 Axle 70 CBM Gasoline Tanker in Djibouti

Dimension: 14500mm * 2500mm *3700mm

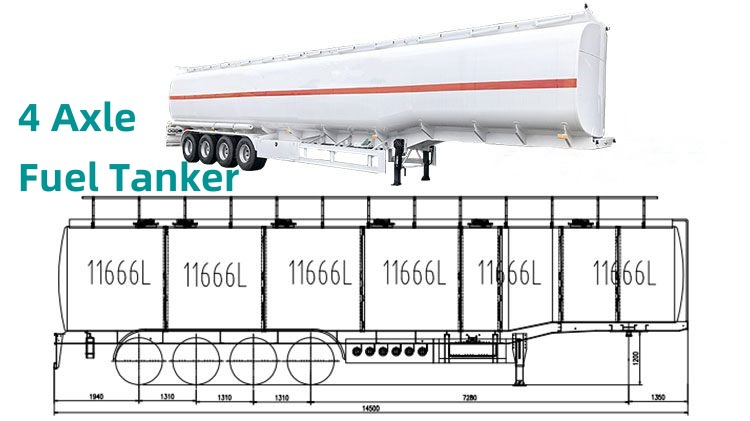

Total volume(m³): 70CBM

Tank Body Material: 5mm carbon steel

End plate: 6mm carbon steel

Compartments: Optional

Axle: 4 axle

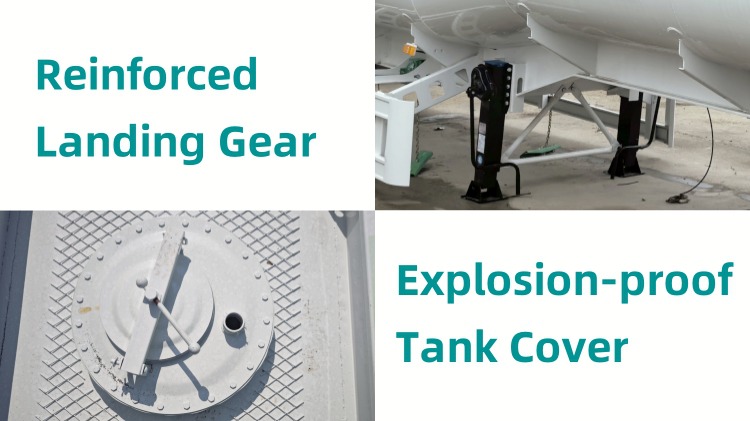

Landing Gear: 28T

Suspension: Mechanical Suspension

Tire: 12R22.5

1. Oil tank shape and capacity

The petrol tanker generally employs a circular tank body design. This design is effective to keep the fluid flowing and stable. Round tank body naturally distributes inside and outside pressure. It's helpful to withstand a higher fluid pressure. The petrol tanker is less likely to be deformed. The petrol tanker owns a capacity of about 70 cubic meters. It owns 6 sub-compartments. They will be distributed flexibly in accordance with traffic requirements. Reasonable capacity design is benificial to maximize cargo loading. Thus, the unit transport cost of petrol tanker will not be high any more.

2. Security configuration

2.1 Prevention of leakage and overflow

Continuous innovation in the sealing technology of petrol tankers. Vertical welding technique is applied to guarantee the integrity of welding seam. Moreover, the safety of petroleum products is guaranteed by pressure testing and metal defect testing. Using overflow valve is vital to prevent oil leakage and reduce environmental pollution. Moreover, the oil and gas recovery valve is designed to recover the oil and gas. It's easy for petrol tanker to decrease environmental pollution. Petrol tanker can be operated in an environmentally friendly manner.

3. Anti-tilt design

The centre of gravity of the petrol tanker has been calculated carefully. To enhance the stability of the ride. The fluid flow may lead to the change of the centre. Therefore, a proper anti-tilt design can be used to prevent rollover accidents.

4. Impact-resistant structure

The wave breaker board of the petrol tanker has been strengthened. It aims to enhance the impact resistance. Ensure effective absorption of shock due to fluid fluctuation while driving. It contributes to better integrity of tank body.

5. Economy of transport

70 Cubic petrol tanker owns high carrying capacity. It is helpful to load more fluid in one shipment. Thus, the efficiency of transport and economic benefits are enhanced. Through a reduction in traffic, it's easy for companies to save fuel costs. Moreover, it is effective to decrease the investment of human resources. It aims to obtain the superiority in the intense market competition.

6. Operation convenience

6.1 Refueling port and oil discharge system

The filling port and the oil discharge port is changed to convenient style. The operation is enbaled to be simple and quick. Reasonable layout is easy to reduce waste of time in operation.

6.2 Anti-theft tank cover

The design of the anti-theft tank cover on the modern tank is helpful to enable the safety. This design is effective in preventing unauthorized opening and destruction. The risk of stealing oil is prevented successfully. Your benefit of the business will be proetcted by petrol tanker.